PT Sejahterabanta Solusi Tama is a specialized company based in Indonesia that focuses on the distribution and assembly of composite hoses. The company provides high-quality hose solutions tailored for industries such as:

Oil & Gas

Petrochemical

Chemical Processing

Marine & Offshore (FSRU, LNG, LPG)

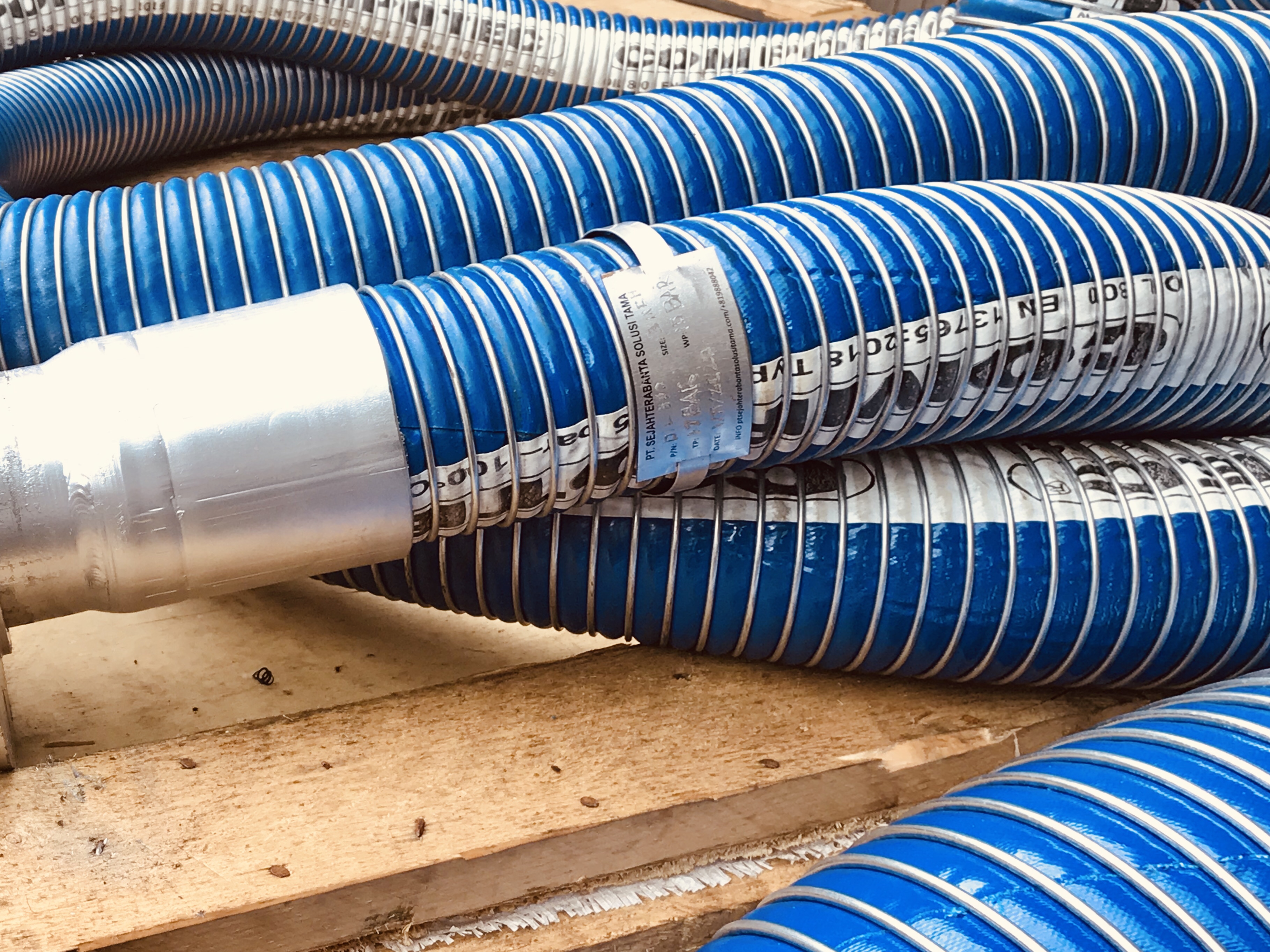

PT Sejahterabanta Solusi Tama is known for supplying Compotec®️ composite hoses, which are internationally recognized for their flexibility, chemical resistance, safety, and durability. These hoses are suitable for the transfer of aggressive fluids, including chemicals, hydrocarbons, and cryogenic gases.

Key highlights of the company include:

Expertise in hose selection for hazardous and demanding environments.

Custom assembly and local support in Indonesia.

Fast response and reliable delivery for critical hose requirements.

Commitment to safety and international standards compliance.

PT Sejahterabanta positions itself as a professional and responsive partner, supporting industrial operations with fast, safe, and reliable fluid transfer solutions.

COMPOTEC CRYOGENIC FOR LPG AND LNG

Temperature -196 Celcius

We Offer Wide Range Of COMPOTEC composite hose such as Oil -Chemical – LPG

PT SEJAHTERABANTA SOLUSI TAMA or knowed as SBA will assist in find correct,safe and efficient for your needs

We are your fluid transfer partner

Phone :+622173664692

Phone: +62819888042

Email:

rioyoshi@ptsejahterabantasolusitama.com

Experience in dock and marine transfer hose

Sejahterabanta STS Hose (Ship-to-Ship Transfer Hose)

Our STS (Ship-to-Ship) composite hoses are specially designed for the safe and efficient transfer of oil, fuel, and chemicals between vessels at sea. Built with multiple layers of high-quality materials, they provide:

High flexibility and strength

Excellent chemical and pressure resistance

Anti-static and vapor-tight construction

Custom lengths and fittings available

All hoses are tested according to international standards and can be tailored to meet specific STS operational requirements.

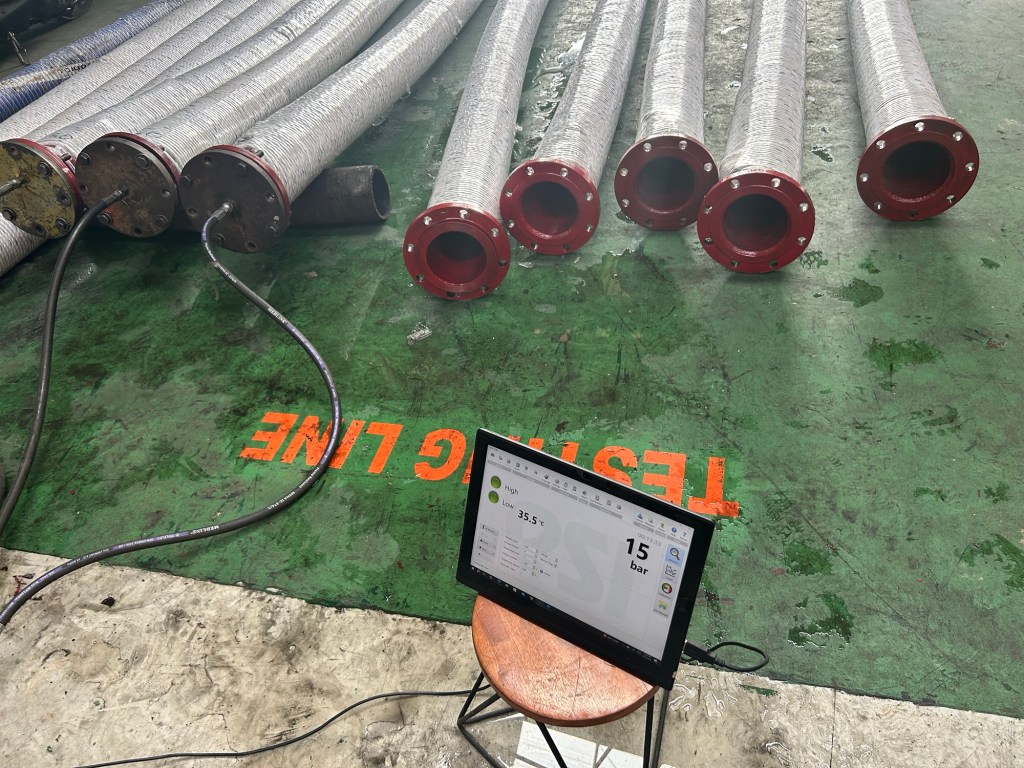

Hose Testing Standards – PT Sejahterabanta Solusi Tama

To ensure product quality, performance, and safety, all hoses supplied and assembled by PT Sejahterabanta Solusi Tama are tested according to internationally recognized standards.

✅ 1. Visual Inspection

Inspection for physical damage, wear, deformation, and connection integrity.

Standards followed: EN 13765 / EN 13766 / ISO 10380

✅ 2. Hydrostatic Pressure Test

Hose is filled with water and pressurized up to 1.5 times the Maximum Working Pressure (MWP).

Test duration: minimum 5–10 minutes.

Must show no leakage or deformation.

Complies with: BS EN ISO 1402 and OCIMF Guidelines

✅ 3. Electrical Continuity Test

Ensures safe discharge of static electricity during fluid transfer.

Maximum resistance requirement: typically < 1 ohm/m (depending on hose type).

Standard: EN ISO 8031, OCIMF Guidelines

✅ 4. Leak Test

Conducted using water or air to detect micro-leakages.

Methods: Bubble test or pressure decay test, depending on application.

✅ 5. Dimensional & Weight Verification

Checks on length, internal diameter (ID), and weight to ensure compliance with technical specifications.

✅ 6. Minimum Bending Radius Test

Hose is bent to the minimum allowable radius to verify flexibility and structural integrity.

📄 Documentation & Certification

Each hose is delivered with a Test Certificate (TC) including detailed test results.

Custom test protocols and third-party witness testing available upon client request (e.g. Pertamina, BP, Shell, power plants, oil & gas projects).

PT Sejahterabanta Solusi Tama – Facility Overview

Our facility is fully equipped to support the production and assembly of high-quality industrial hose systems. Key capabilities include:

Crimping Machine: Capable of handling hose assemblies up to 12 inches in diameter, ensuring strong, secure, and leak-free connections.

Machining Workshop: Precision machining services to support custom fittings, connectors, and hose accessories tailored to client specifications.

Welding Station: Professional welding for stainless steel and carbon steel components, including hose fittings and flanges, supporting high-pressure and high-temperature applications.

We are committed to delivering reliable, safe, and efficient solutions for the oil & gas, chemical, and energy industries.

Our Wide Range of Hose Stock

We maintain a comprehensive inventory of composite, flexible metal, and rubber hoses in various sizes, pressure ratings, and chemical compatibilities to ensure fast delivery and reliable solutions for our customers’ diverse applications.

For inquiry please contact

021 73664692

0817888 979

Admin@ptsejahterabantasolusitama.com